Mobile phones run on so-called embedded chipset which are designed to perform one or sometimes multiple dedicated functions. They are embedded into the entire device, including hardware and mechanical components. Thus the CPU (Central Processing Unit) in smartphones is vital for the daily user experience and we compare the performance of different CPUs according to the clock rates. Although a processor’s clock rate is only helpful for providing comparisons of output between computer chips in the same processor family and generation.

In essence, an SoC or SiP is an integrated circuit or IC that requires a single platform and incorporates an entire device or electronic system into it.

What is an SoC?

SoC stands for System-on-a-Chip. An SoC is a full processing device housed in a single box, as the name suggests. It’s not a single chip kit for a processor, which you might be familiar with if you ever designed a PC. An SoC contains various processing parts like memory, modems, and other essential parts and pieces. These parts are manufactured together in a single chip and then soldered onto the circuit board. The reason why SoCs were adopted is that because of the size limitations of the smartphone devices, SoCs take up far less space compared to others. However, the need to have more components such as larger batteries, multiple sensors, and cameras with large sensor sizes is growing as smartphones continue to become more and more efficient, but the overall form factor of a smartphone still needs to be kept at a smaller size.

There are three different types of SoCs:

- SoCs having a microcontroller in operation (a chip with the CPU, RAM, ROM, and potentially other components). Example: Boards with Arduino.

- SoCs that use a microprocessor (a chip with a CPU only). Examples are mobile SoCs, such as Qualcomm’s Snapdragon and the Apple A12 Bionic SoC used on iPhone users.

- ASIC (application-specific integrated circuit) SoCs, that may or may not use a microprocessor or microcontroller for particular applications.

What is SiP?

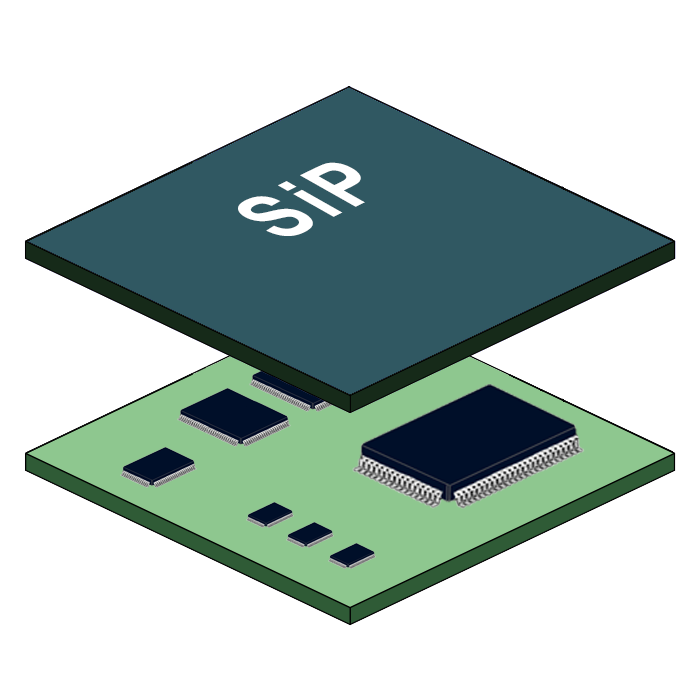

SiP stands for System-in-Package. Basically, what this means is that all the main components that make the phone work are combined into a single package that is then soldered to the motherboard. SiP means faster growth with lower costs than SoC. While SiPs are not new, the use of this technology in smartphones is new, most of the manufacturers were using SoCs until recently when Qualcomm released its first Snapdragon SiP 1 chipset, which debuted on the latest Asus phones launched in Brazil.

A lot of people are unaware but the apple watch “S” series is also using SiP chips for space constraint in their small watches. While it can be argued that an SoC is also exactly the same, the key distinction lies in both the production process and the physical size and space they occupy.

SiPs are designed in three ways:

1.SiP and chip-scale packaging

2.Side-by Side SiP

3.Chip-on-chip SiP designs

To know about them you need prior knowledge of microprocessors and ICs but in this article, we are not going into too many details about all those designs.

What's the difference between them?

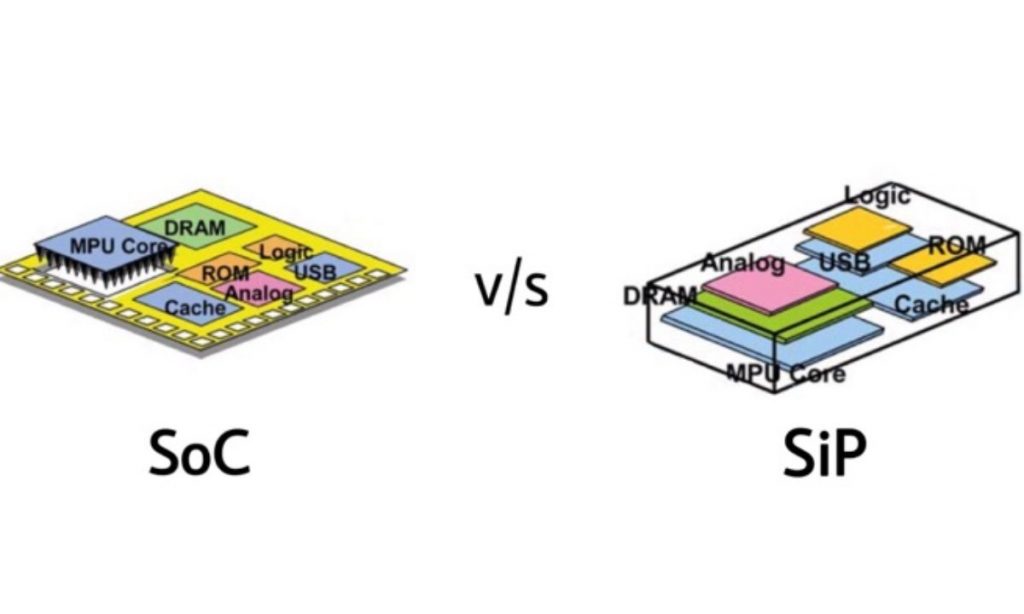

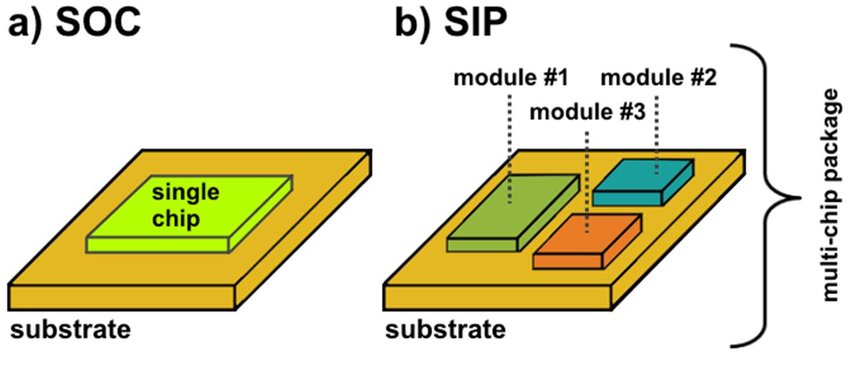

SiP, is a way to combine two or more ICs within a single package. This is in contrast to an SoC, where the functions are combined on those chips on the same die.

Since an SoC is basically all components on an IC (Integrated Circuit), every component is manufactured on the same manufacturing process. This means, when we say that the Snapdragon 855 is based on the 7nm manufacturing process, it means that the CPU, GPU, RAM, etc. are all manufactured on the same process as the entire SoC is manufactured using just one single die. Well, what is a die? A die is a formal term for a silicon chip comprising an integrated circuit. Die is plural, and dice is singular. Sometimes, the words die and the chip is synonymously used. In another word, a die is a micro-manufactured semiconductor component, while a chip is the packaged die (or multiple dice).

The circuitry is mapped to a Silicon die which is then transformed to a chip using different processes, and for those of you who are unaware of the development process of these chips.

An SoC is created using only one single die so that each component’s manufacturing process remains exactly the same. This takes up more room as the different ICs are put on the PCB next to each other and are scattered over a wider area.

On the other side, the SiP does not include all the elements in one single die but instead has numerous chips stacked on top of each other. This saves room as the ICs need not be scattered around the PCB, and piling them up does not increase the total thickness by much as the chips themselves have extremely small thicknesses. What this also means is that, because the SiP is not just a single chip, separate dies are used to create the individual ICs, which means that each part of the chip can be made using a different process.

The benefit of SiP over SoC

Nowadays smartphones are cramming up multiple cameras, using a large battery, and all these require more space but the manufacturer needs to make them compact so that they don’t end up looking ugly and boxy like the old phones. Some manufacturers are also sacrificing important components like the headphone jack to accommodate more space for other parts. SiPs can help by managing up the space constraint for the chips and boards as their physical size is more concise and they need less space than SoC chips.

SiPs are not going to replace the SoCs overnight, they are at a very early stage. there are only very few smartphones using this technology and they are exorbitantly priced. SiPs are still a work in progress and it is the right step toward more compact mobile devices in the near future as it allows for more space inside our electronics.